Geo composite Manufacturers

Stelka Textiles has emerged as one of the most reputed Geocomposite Manufacturers in India. We are dealing into a variety of geotextile products that are helpful in offering support in drainage, filtration, soil stabilization, and several civil engineering applications. We are into this business segment since 2016 and are well aware of the kind of geocomposite required for these applications. We ensure that we utilize excellent grade geosynthetic materials to deliver our customers with high efficiency geocomposite.

The utilisation of geocomposite in multiple applications requires us to produce geocomposite made of different materials. The availability of experts at our manufacturing unit helps us serve the market with diversified geocomposites in India. At Stelka Textiles, we have experts who have in depth knowledge about different types of geosynthetic materials. They are well aware of the properties of this material and fabricate a geocomposite accordingly to meet different requirements including filtration, separation, reinforcement, drainage, and a few more.

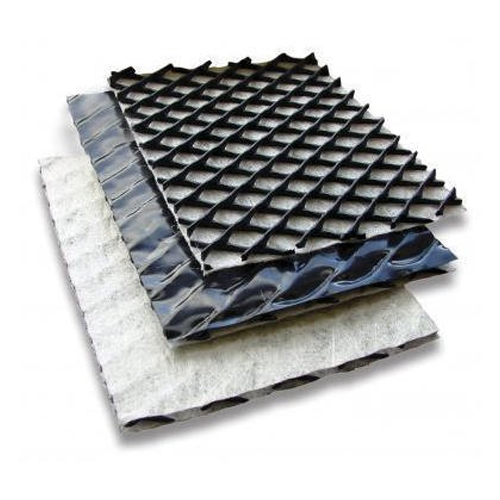

Being one of the prominent Geocomposite Manufacturers, we always use impeccable quality material for manufacturing these grids. Though they are light in weight but are excellent when it comes to bearing load. We have designed the grid structures of the geocomposite in a way that they can easily distribute the load without getting damaged.

We are known for manufacturing Geocomposite of different types and with varying thicknesses. Though, most of our geocomposite are three-dimensional structures which are suitable for stabilization purpose. At Stelka Textiles, we have geocomposite of different sizes available to help our customers choose according to their requirements. Being one of the ISO approved Geocomposite Manufacturers in India we always maintain quality in our products. While manufacturing these, we not only focus on their quality but also focus on their durability. That is why our Geocomposites are long lasting and support several applications.

We at Stelka Textiles are known for supplying Geocomposite for several applications that includes landfills, road construction, highway, green roofs, railway, airport, pollution control, soil erosion, retaining walls, groundwater management, and several other applications. We are known for manufacturing geocomposite in bulk quantity and are capable of fulfilling demand of several clients with ease. All our geocomposite are available at nominal market prices.

Features of Geocomposite :

1 Lightweight:2. Flexible

3. Powerful

4. Drainage-Friendly

5. Eco-friendly